Inspection Geni Product Description

FAQ for Designers & Inspection Room Manegers

- Is my dimension ID and inspection report table a part of the release production process?

- Is engineering the right place to start the process?

- Would engineering like to receive inspection reports from different manufacturers with the same dimension ID?

- Would engineers be interested in reviewing a history of ID dimensions?

- Does numbering on a drawing paper and copying of all measurements manually into Excel or any other software consume valuable time?

- Can an automated design process save you valuable time, enhancing accuracy and eliminating errors?

- Can your inspection reports be saved in a database allowing you to conduct searches on the quality of parts, quality of manufacturer, problematic areas, etc?

- Can you do away with the dusty archives of manual audit reports?

- Can you pull a particular report in seconds when clarification is needed with a customer or a manufacturer?

Inspection Geni allows manufacturers to expedite business processes, automate approval processes, slash costs and enable paperless documentations for storage and retrieval.

Inspection Geni has the Answers

Manufacturers worldwide invest millions of dollars automating their operations and business processes.

As a result paper documentation permeates every aspect of your business increases organizational costs, requiring additional time, and prohibiting your organization from realizing the true benefits of a fully electronic workflow.

Inspection Geni allows you to close the gap in going fully paperless by completely eliminating the need to print documents for inspection using its fast, low-cost, and fully digital system.

Features at a glance:

Sorting

Automatically sort designs, creating a dimensional database giving you a perfect interface to plan your inspection process.

Planning

Plan the inspection of a particular product part by creating a template defining the measuring tools and related tolerances.

Inspection

Print blank inspection reports for sorting using the measurement tool with different inspection stations, like high gauge, CMM and manual inspection.

Documentation

Automatically print inspection documents and MRB reports, so you can answer questions put to you by customers on mechanical changes, etc.

Archive

Save the technical changes history made to any manufactured part and archive all the correspondence with the designer including attached documents, emails and drawings.

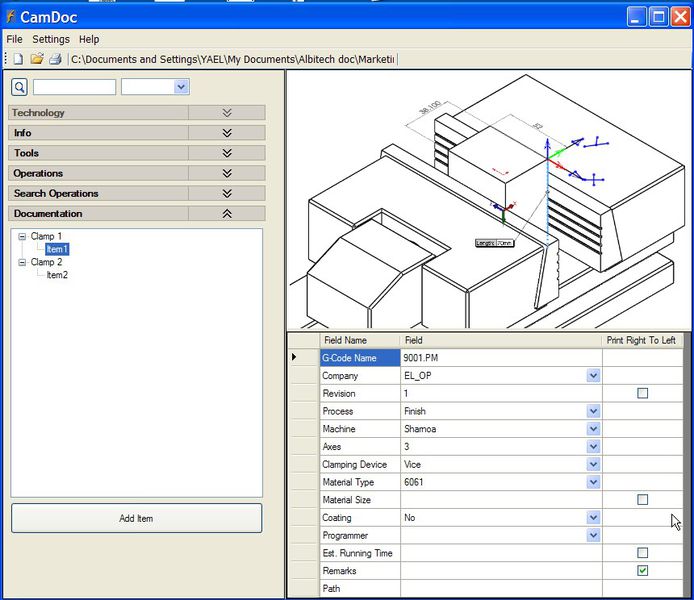

SolidWorks Integration

Inspection Geni’s fully automated workflow reduces the expenses and time allocations of paper-based designs.

Due to its seamless integration with leading solutions, such as SolidWorks, Inspection Geni enables the designer to analyze dimensions and automatically add the data into the inspection template. The dimensions are stored allowing a user to immediately view the highlighted connected dimensions, saving considerable time when preparing the inspection process.

Inspection Geni for Engineers

This version of the software is designed to meet the specific needs of your engineering department.

Inspection Geni for Engineers enables the fast creation of a drawing with dimension ID and an inspection report that will be delivered to the producer together with the model.